PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

5A05 aluminum is a multifunctional alloy with a wide range of properties and uses. It has excellent corrosion resistance, excellent weldability, good formability and machinability, and medium strength. Due to its versatility, this alloy is used in many industries and applications-from automotive components to cookware to electrical enclosures.

5083 aluminum is a non-heat-treatable alloy known for its resistance to extreme environments, including seawater corrosion and industrial chemicals. Although Al-5083 has limited machinability due to its strength, it is a material for marine and aquatic applications and is commonly used in the shipbuilding industry. Other uses for this alloy include transportation applications such as railroads, trucks, and car bodies, as well as pressure vessels and food processors.

Among the various properties of 6061 aluminum, it is considered to be versatile, easy to process, and relatively inexpensive. It is used in aerospace engineering, aircraft and helicopters, screw machine parts, yachts and boats. It is also very suitable for tank bodies, bicycle frames, structural parts, food and beverage cans. You will also find that 6061 aluminum is often used in car chassis, truck frames, flashlights, fishing line wheels, pistol suppressors, cover plates and platforms, vacuum chambers, etc.

7075 aluminum alloy is an aluminum alloy with zinc as the main alloying element. It has excellent mechanical properties, showing good ductility, high strength, toughness and good fatigue resistance. Due to the presence of microsegregation, it is more brittle than many other aluminum alloys, but has significantly better corrosion resistance than 2000 alloys. It is one of the most commonly used aluminum alloys in high-stress structural applications and has been widely used in aircraft structural components.

304 stainless steel is a kind of universal stainless steel material, rust resistance than 200 series of stainless steel material is stronger. High temperature resistance is also better, can be as high as 1000-1200 degrees. 304 stainless steel has excellent corrosion resistance and good intergranular corrosion resistance. For oxidizing acids, it is concluded in the experiment that 304 stainless steel has strong corrosion resistance in nitric acid with a concentration of less than or equal to 65% of the boiling temperature. It also has good corrosion resistance to alkali solution and most organic and inorganic acids.

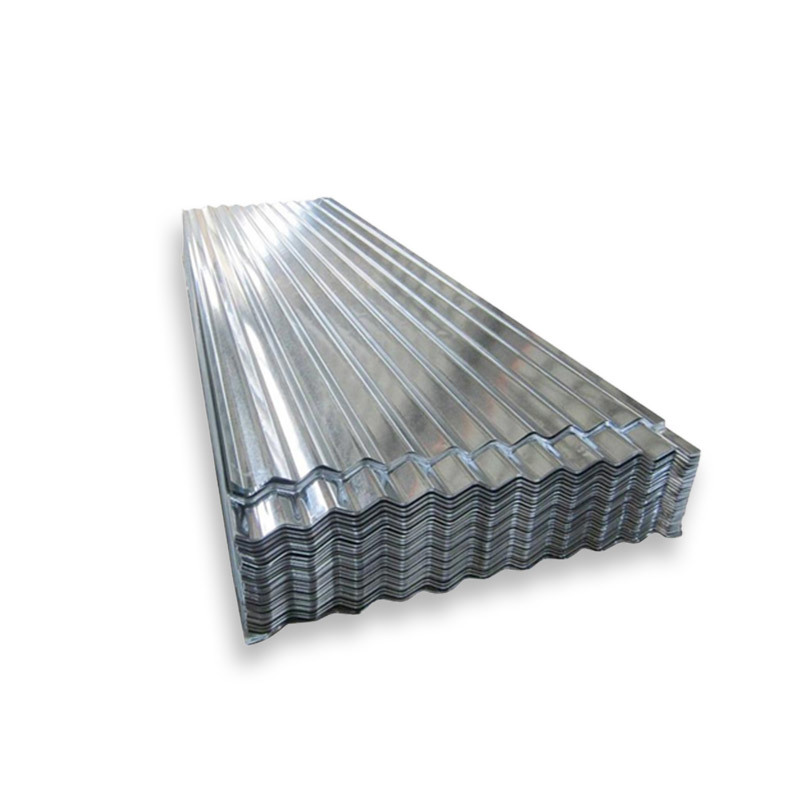

Galvanized Corrugated Roof Sheet

Galvanized roof shingles are made of galvanized steel sheet used for roofing and coated with zinc. The zinc coating provides moisture and oxygen protection for the base steel. According to the galvanizing process, it can be divided into hot-dip galvanized steel plate and electro-galvanized steel plate. The corrugated design will improve its strength and enable it to withstand harsh weather conditions. Common designs include wavy, trapezoidal designs, ribbed galvanized roof panels, etc. It can be used as a single-layer board, covering an existing roof, or a steel sandwich panel.

A36/Q235/S235JR Carbon Steel Plate

A36 is a low-carbon steel containing trace amounts of manganese, phosphorus, sulfur, silicon and other elements such as copper. A36 has good weldability and high yield strength, and is the structural steel plate specified by the engineer. ASTM A36 steel plate is often manufactured into a variety of structural steel parts. This grade is used for welded, bolted or riveted construction of bridges and buildings, as well as for general structural purposes. Due to its low yield point, A36 carbon plate can be used to design lighter weight structures and equipment, and provide good weldability. Construction, energy, heavy equipment, transportation, infrastructure and mining are the industries where A36 panels are commonly used.

A572/S355JR Carbon Steel Plate

A572 grades are divided into: 42, 50, 60, 65. The steel plate is light in weight, but has good strength, ductility and workability, making it an ideal choice for structural applications. These characteristics make the A572 relatively simple to shape into different structures, while maintaining the ability to withstand large stresses and loads.